1. Material options

- Heavy guage steel is used for the external steel panels and structural elements, featuring the Baltiplus 800TM material option.

- The casing sides panels are made of FRP (Fibreglass Reinforced Polyester) are light and can be easily slid upwards to access the heat exchange coil.

- Optional stainless steel panels and structural elements with type 304L or 316L construction is available for additional corrossion resistance.

- Or the economical alternative: a water-contact stainless steel cold water basin. Its key components and the basin itself are stainless steel.

2. Heat transfer media

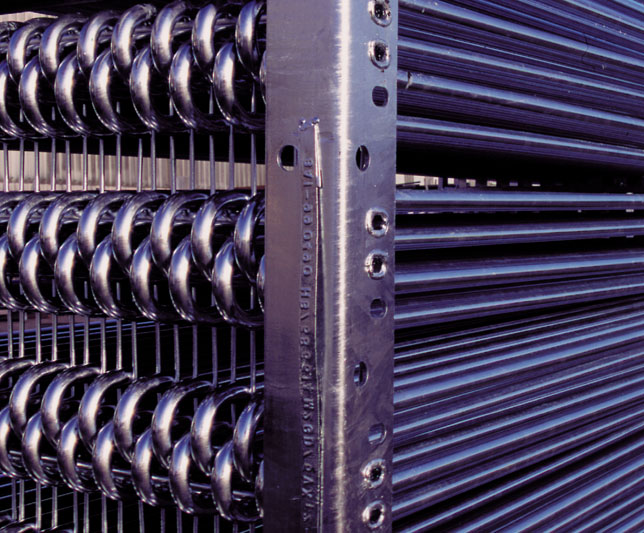

Our heat transfer media is a cooling coil. In comprehensive lab thermal performance tests, it showed proved thermal cooler performance and offers you unrivalled system efficiency.

Our heat transfer media is a cooling coil. In comprehensive lab thermal performance tests, it showed proved thermal cooler performance and offers you unrivalled system efficiency.- The coil is constructed of continuous length of prime surface steel, hot-dip galvanized after fabrication. Designed for maximum 10 bar operating pressure according to PER.

- Sloped tubes for free drainage of the coil.

- Optional stainless steel coils are in type 304L or 316L.

3. Air movement system

- FCI fan system features low kW and noise axial fan(s) in corrosion resistant aluminum, with polypropelyne blades encased within the fan cylinder with removable fan guard.

- Models FCI 18-0 to FCI 180-4 use multiple independantly driven fans, providing the user with additional capacity control.

- Larger units use optimally selected V-belt drives, furnished with a steel fan shaft and heavy duty ball bearings and extended lubrication lines, this guarantees optimal and year-round operational efficiency. This drive system is encased in a steel with a large access door.

- Our drift eliminators come in UV-resistant plastic, which will not rot, decay or decompose. They are assembled in easily handled and removable sections, for optimal internal access.

- Easy removable UV-resistant plastic combined inlet shields at air inlet, block sunlight to prevent biological growth in tower, filter air and stop water splash-out.

4. Water distribution system

These consist of:

- Spray branches with non-clog plastic nozzles secured by rubber grommets.

- Easy accessible sloped cold water basin, including anti-vortexing steel strainer, make up and overflow connection.

- Close coupled, bronze fitted centrifugal spray pump with totally enclosed fan cooled (TEFC) motor.

- Bleed line with metering valve is installed from pump discharge to overflow.

Interested in the FCI cooling tower? Contact your local BAC representative.